- R & D · manufacturing

Snow machine & Snowflake machine

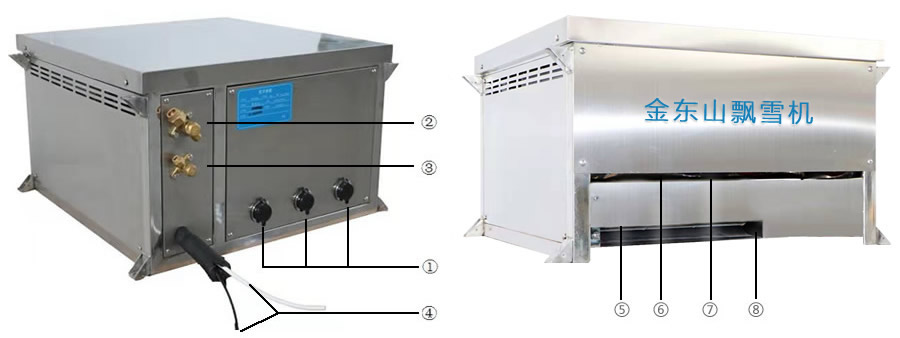

| ① | Internal and external cable inlet | ⑤ | snow outlet |

| ② | Low pressure pipe | ⑥ | roller |

| ③ | High pressure pipe | ⑦ | water box |

| ④ | Inlet pipe heating | ⑧ | fan port |

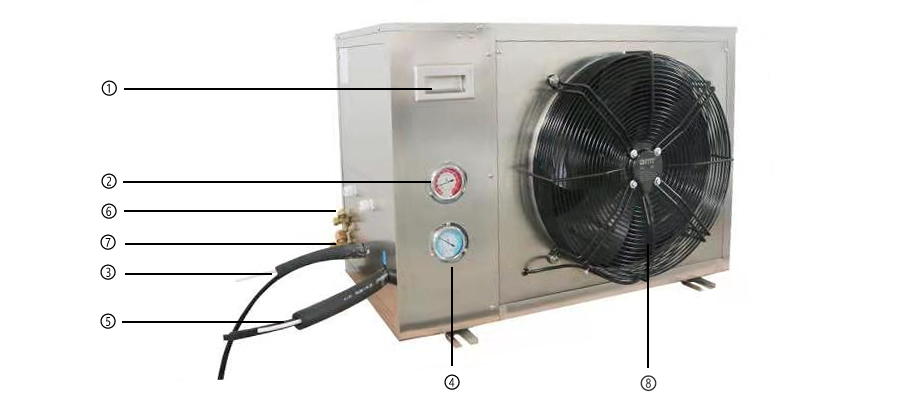

| ① | Handle | ⑤ | outlet pipe |

| ② | High pressure meter | ⑥ | high pressure pipe |

| ③ | Water inlet pipe | ⑦ | low pressure pipe |

| ④ | Low pressure meter | ⑧ | condensing fan |

|

Type no |

DS-200N |

|

Amount of snow |

260kg/day |

|

work environment |

-25℃~10℃ |

|

Compressor power |

2p |

|

Snowblower power |

1500w |

|

Power Supply |

220V 50Hz |

|

Snow area |

0.5m²-15m² |

|

Installation height |

2.5m↑ |

|

Dimensions |

Dimensions: l 600X w 540x h 332 Dimensions: length 886x width 604x height 603 Control box: length 500 * width 400 * height 200 |

| Weight |

Internal weight: 42kg External weight: 78kg Control box: 15kg |

|

Working conditions |

Water and electricity supply |

|

Water pressure |

The height of water pressure is based on the height of the hanging machine, about 0.3MPa (water inlet outlet pressure) |

|

Pipeline length |

The length is 15m, and the height difference is not more than 5m (measures shall be taken when exceeding this range) |

|

control mode |

Control box button |

|

Mounting hole size |

565mm(snow outlet)X 510mm |

| phenomenon | Possible causes of failure | Inspection content | processing method | remarks |

| The indicator light doesn't work, the machine doesn't work |

1 input no voltage 2. The fuse is blown 3 poor contact between plug and socket 4 switch not on |

1. Measure the voltage to see if there is electricity 2 is the fuse blown 3. Is the socket firmly inserted 4 is the switch set to the on position |

1 normal power supply 2. Replace the fuse 3 insert the plug firmly 4 turnzthe switch to the on position and press the power switch |

General electrical repair |

| The red light is on when the water is not enough |

1. The machine is short of water 2 circuit board F2 fuse blown 3 solenoid valve failure 4 liquid level device failure |

1 section inspection of waterway 2. Check if F2 fuse of circuit board is burnt out (L13 light on indicates F2 is broken) 3. The solenoid valve coil is broken 4 is there any foreign matter in the level gauge |

1. Confirm the water supply and open the water valve, and ensure the water pressure of 0.3kg/cm2-0.7kg/cm2 2 replace F2 fuse (1a) 3 replace the solenoid valve 4 remove foreign matters and keep the liquid level device flexible |

Professional maintenance |

| The water box inside the machine keeps overflowing |

1 water box not installed smoothly 2. Automatic detection of water level signal out of control, water inlet solenoid valve blockage or solenoid valve failure 3 liquid level device failure |

1 is the water box installed smoothly 2 check whether the automatic detection water level signal circuit or the water inlet solenoid valve is blocked or broken Check whether the water level valve is stuck or collides with the water box Solenoid valve coil broken 3. The liquid level switch is broken |

1. The installation is stable and the screws are fixed in place 2 remove the water level signal switch or solenoid valve to remove the blockage and replace the solenoid valve; 3. Replace the level gauge |

Professional maintenance |

| The machine works, but it doesn't make snow |

1 evaporator motor failure 2. Dust accumulation in evaporator 3 refrigerant leakage |

1. Check the motor and circuit Less or no snow production 3. Check whether the system pipe is blocked or leaking |

1. Repair the motor and circuit, and replace it if it is damaged 2. Remove dust to ensure heat dissipation 3. Check leakage, repair welding and add refrigerant |

Professional maintenance |

| The snow roller doesn't work | Over current protection or damage caused by overload operation of drive motor |

1 check if F2 fuse of circuit board is burnt out (L13 light on indicates F2 is broken) 2 check whether the carbon brush of the motor is worn and cannot conduct electricity 3 check the power on condition of motor and winding resistance |

1. Replace 1A fuse 2. Replace the carbon brush 3. Replace the motor |

Professional maintenance |

| The compressor doesn't work | Thermal protection or damage caused by overload operation of compressor |

Check the power on condition and winding resistance of the compressor; Test start after 30 minutes of shutdown |

Start up after 30 minutes of shutdown; Replace the compressor |

Professional maintenance |

| Abnormal noise, too loud |

The box is not placed stably The compressor and fan are not fixed firmly or the pipeline collides |

1 are the four casters on the ground 2 is the screw tight 3. Whether the pipelines collide |

1. Timely pad 2 fastening screw 3. Adjust the pipe spacing to avoid collision or scratch |

General electrical repair |

| Abnormal snow or borneol | The snow plough tool is blunt | There is a lot of noise when ploughing snow | Replacing snow cutter | General electrical repair |

|

|

| Ice and snow art museum | meteorological bureau |

|

|

| 商场迎宾飘雪机 | Ice sculpture Hall |

|

|

| snow festival | Children's Playground |

|

|

| hot spring | Indoor ski resort |

|

|

| Barbecue shop | Sauna ice room |

| Product name | Jindongshan snow machine | ||

| Product Type | |||

| Purchase date | |||

| you name | TEL | ||

| Add | FAX | ||

| service hotline:+8610-64718232 | |||